Vibratory Bowl Feeding of Microscopic Parts

Student

Institution

建筑学英文论文代写 The study has shown that the rotating motion of the feeder bowl generates two forms of manipulations: intermittent and continuous tapping.

Table of contents 建筑学英文论文代写

Abstract…………………………………………………………………………………………..…….…1

Introduction…………………………………………………………………………………….……….2

Background……………………………………………………………………………………..……….3

Review…………………………………………………………………………………………..…………4

Principles of unidirectional feedings……………………………………………………………5

Introduction to ceramic capacitor………………………………………………………………..6

Ceramic dielectric materials………………………………………………………………………..7

Feeding experiment of 0630 capacitor………………………………………………………….8

Bowl feeder accommodation design……………………………………………………………..9

Electrosort bowl feeder………………………………………………………………………….……10

Feeding simulation and comparison…………………………………………………………….11

Conclusion…………………………………………………………………………………………………12

References…………………………………………………………………………………………………13

Appendices……………………………………………………………………………………………….14

Abstract

The vibratory bowl feeder is among the oldest approaches that are applied in automated feeding of microscopic industrial parts. Indeed, most of the manufacturing processes use this technique to orient parts before packing or assembling them. A planar part is polygonal when it has a polygon shaped convex hull. This paper evaluates a group of vibratory bowls which are analyzed by eliminating some polygonal sections. These filtered feeders are known as the traps.

Furthermore, the research study entails describing polygonal parts with unknown orientation,calculating the shortest sequence for a mechanical gripper, as well as finding the symmetry of a convex hull. The study will indicate that n-sided and m-sided polygons are intertwined with O algorithm to facilitate determining the orientation of the feeders in the trap. Both m and n sided convex polygons are improved by O ((n+m) log n). 建筑学英文论文代写

This expression will be advanced to design trap feeds of different shapes, ranging from simple polygons to the advanced polygons. Several parameters will be employed in designing the industrial part feeder with wide range of assembling polynomials. Still, vibratory manipulator will play a key role in manipulating the traps into the desired designs, with both intermittent and continuous tapping as the determinants of the design developed. Intermittent tapping is a form of manipulation where the object comes to rest between impacts whereas continuous tapping is a form of manipulation where object moves constantly.

译文:

摘要 建筑学英文论文代写

振动碗式喂料机是应用于微型工业零件自动喂料的最古老的方法之一。事实上,大多数制造过程都使用这种技术在包装或组装零件之前对其进行定向。当平面部分具有多边形凸包时,它是多边形的。本文评估了一组振动碗,通过消除一些多边形截面进行分析。这些过滤后的喂食器被称为陷阱。

此外,研究需要描述未知方向的多边形部件,计算机械夹具的最短序列,以及找到凸包的对称性。该研究将表明 n 边和 m 边多边形与 O 算法交织在一起,以促进确定陷阱中馈线的方向。 m 和 n 边凸多边形都改进了 O ((n+m) log n)。

此表达式将用于设计不同形状的陷阱馈送,范围从简单多边形到高级多边形。在设计具有广泛组装多项式的工业零件进料器时,将采用几个参数。尽管如此,振动机械手仍将在将陷阱操纵成所需的设计方面发挥关键作用,间歇性和连续性攻丝是设计的决定因素。间歇敲击是一种操纵形式,其中物体在两次撞击之间静止,而连续敲击是一种操纵形式,其中物体不断移动。

Introduction

A part feeder is one of the machine components widely known for its efficiency at work. It takes the identical parts via arbitrary orientation, synthesizing them, and then outputting them uniformly. The approach under study considers the sensorless orientation where the initial direction of the parts is unknown. In this method, parts are oriented passively using mechanical compliance.

Input refers to the fraction of a design while output is the operations in an open loop which are responsible for orienting the parts of the design from unknown point to a unique area (Maul & Thomas, 1997, p 243-250). These operations constitute the final orientation procedures which are essential in eliminating the deformed products. Examples of the sensorless part feeders used in the manufacturing processes are parallel-jaw gripper, peshkin and sanderson, tilting tray, single pushing jaw, conveyor belt, and the vibratory plates. 建筑学英文论文代写

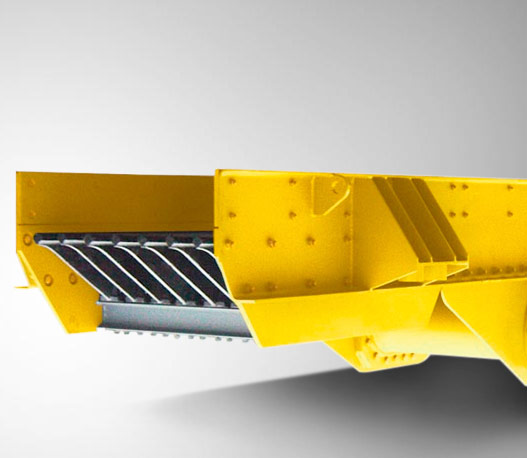

Vibratory bowl feeder consists of a bowl filled with several parts of helical metal track. Both bowl and helical metals are turned by the vibratory motion of the mechanical devices, causing parts to surge upward in the line with the wiper blades, traps and the grooves. These devices are positioned such that they are able to filter the disoriented and malformed parts back to the base of the bowl. The desired parts emerge at the top of the bowl after successfully passing through the gauntlet sieve. This study highlights on the procedures that are involved in filtering polygonal parts from a feeder trap.

A trap denotes the action of eliminating the polygonal parts from the track. Parts move along the feeder from right to left, allowing filtration and subsequent operations to take place. See Figure 1.

译文:

介绍

零件送料器是以其工作效率而广为人知的机器组件之一。它通过任意方向获取相同的部分,将它们合成,然后统一输出。所研究的方法考虑了无传感器方向,其中零件的初始方向未知。在这种方法中,零件使用机械顺应性被动定向。

输入是指设计的一部分,而输出是开环中的操作,负责将设计的各个部分从未知点定向到独特区域(Maul & Thomas,1997,第 243-250 页)。这些操作构成了消除变形产品必不可少的最终定向程序。制造过程中使用的无传感器零件送料器的例子有平行爪抓手、peshkin 和 sanderson、倾斜托盘、单推爪、传送带和振动板。

振动碗式给料机由一个装有几部分螺旋金属轨道的碗组成。碗状金属和螺旋状金属都通过机械装置的振动运动转动,使零件与雨刮片、陷阱和凹槽一起向上涌动。这些装置的位置使得它们能够将方向错乱和畸形的部分过滤回碗的底部。成功通过手套筛后,所需的部分出现在碗的顶部。本研究重点介绍了从馈线陷阱过滤多边形部件所涉及的程序。

陷阱表示从轨道中消除多边形部分的动作。零件沿着进料器从右向左移动,从而可以进行过滤和后续操作。参见图 1。

Vibratory bowl feeders are efficient machines that shoulders most of the automatic operations.

They orient parts which are utilized in design work. Different algorithms are applied to promote automatic operation of vibratory feeder. This study focuses on algorithm that synthesizes the information of part geometry and generates a plan for running the gripper. The squeeze action, α, is a combination of orienting the gripper at an angle with respect to both closing and opening jaws. Two squeeze actions, ‹0, ∏∕4 › ensure that major axis of the parts are aligned with respect to the gripper. Notably, the preparation on the above procedures requires only mechanical compliance (Ting, 2005, p 266).

Other devices such as the ceramic capacitors and the resistors are commonly used in sorting and inspecting the produced microparts.

In micropart feeding, the technicians must ensure that the driving force applied on microparts resonate with the direction of the movement of the microparts. Notably, the microparts that are smaller than the submillimeter could be altered by either inertia or adhesion forces. These forces are triggered by the electrostatics, surface tension, intermolecular and Van der Waal forces which develops in the mechanical devices. Therefore, necessary measurements such as applying dynamics are essential to counteract the undesired outcomes from the movement of the microparts. 建筑学英文论文代写

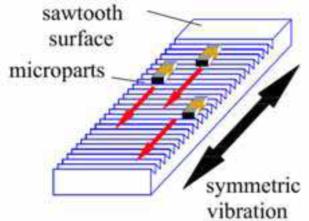

Sawtoothed surface are also efficient in feeding the microparts because they posses simple planar and symmetric vibrations. Its operations are attained either by point contact or slope contact on the microparts. The major difference in variation of the contact area of the microparts is brought by the direction of rotation of the microparts inside the feeder bowl. In addition, the driving forces of the vibrations onto the microparts, in the feeder surface, vary depending on area of contact. It outcome is that microparts are oriented into a simple planar symmetric vibrations. Figure 2 indicates a microparts feeding on a sawtoothed surface.

译文:

振动给料机是高效的机器,可承担大部分自动操作。

他们定位在设计工作中使用的部件。采用不同的算法促进振动给料机的自动化运行。本研究侧重于综合零件几何信息并生成运行夹具的计划的算法。挤压动作 α 是相对于闭合和打开夹爪以一定角度定向夹持器的组合。两个挤压动作,‹0, ∏∕4 › 确保零件的主轴相对于夹具对齐。值得注意的是,上述程序的准备只需要机械顺应性 (Ting, 2005, p 266)。

其他设备,如陶瓷电容器和电阻器,通常用于对生产的微零件进行分类和检查。

在微型部件进料中,技术人员必须确保施加在微型部件上的驱动力与微型部件的运动方向产生共振。值得注意的是,小于亚毫米的微型部件可能会被惯性或粘附力改变。这些力是由机械设备中产生的静电、表面张力、分子间力和范德华力触发的。因此,必要的测量(例如应用动力学)对于抵消微零件运动产生的不良结果至关重要。

锯齿形表面也能有效地供给微零件,因为它们具有简单的平面和对称振动。它的操作是通过微零件上的点接触或斜面接触来实现的。微零件接触面积变化的主要差异是由进料碗内微零件的旋转方向引起的。此外,振动对供料器表面微零件的驱动力因接触面积而异。结果是微型部件被定向成简单的平面对称振动。图 2 显示了在锯齿状表面上进给的微型零件。

Background 建筑学英文论文代写

Vibratory feeder is rooted from two theories. They are theory of compliant planning and theory of mechanical analysis.

a)Theory of compliant motion

Its objective is to find path of a motion from an assumed position to the desired point. With this technique, the initial location of the microparts is not known and the objective is to locate where the parts should be positioned to promote production of quality products. This theory denotes that it would be easy to move a robot in a closed room through northern and southern direction provided there are no obstacles in the room. This means that the compliant motion is likely to reduce uncertainty with the mechanical processes.

The geometric approach to complaint motion assumes a robot in space within specific configuration. Commands fed into the robot are similar to those fed into the vibratory bowl feeder. The mechanical properties such as friction, stability and kinematic constraints are linked to the geometric attributes of this space. The initial conditions and the desired configuration of the feeder bowl are represented as a subset of the design space such that its true configuration is retained. Moreover, the approach facilitates presenting the uncertainty in the outcome of the product by mapping the motion of the microparts.

One of the major ways of developing an automatic working plan is by working backwards through a process known as preimage backchaining.

The geometrical region of configuration is determined by projecting the strong preimage zone. This is achieved by chaining the vibratory feeder backwards via altering the initial sequence of the configurations. Mitani and Hirai, (2007) showed how the plan could be generalized to facilitate efficient performance in the production line. Still, they focused on the methods to reduce both the model errors and the plan failures through manipulation of the planning algorithms. Numerical method was credited for planar compliant motion that is strong to counteract uncertainties in position, orientation, and mass distribution. Many algorithms are likely to create complete approach for a guaranteed compliant motion. 建筑学英文论文代写

A coded vibratory feeder executes compliant motion by rotating within a stable configuration of closed jaw. Analogously, the sliding of the parts along the bowl assumes grippers actions which determines the orientation of the microparts without resorting onto the sensors. Other approaches that could be effective in the configuration of the vibratory feeder are open-loop, oblivious and sensorless manipulations.

译文:

背景

振动给料机源于两种理论。它们是顺从规划理论和力学分析理论。

A)顺应运动理论

它的目标是找到从假定位置到所需点的运动路径。使用这种技术,微零件的初始位置是未知的,目标是定位零件应该放置的位置,以促进优质产品的生产。该理论表明,只要房间内没有障碍物,在封闭的房间内通过南北方向移动机器人将很容易。这意味着顺应性运动可能会减少机械过程的不确定性。

抱怨运动的几何方法假设一个机器人在特定配置的空间中。输入机器人的命令类似于输入振动碗式给料机的命令。摩擦、稳定性和运动学约束等机械特性与该空间的几何属性相关联。进料碗的初始条件和所需配置表示为设计空间的子集,以便保留其真实配置。此外,该方法通过映射微型部件的运动,有助于呈现产品结果的不确定性。

制定自动工作计划的主要方法之一是通过称为原像回链的过程向后工作。

配置的几何区域是通过投影强原像区来确定的。这是通过改变配置的初始顺序将振动给料机向后链接来实现的。 Mitani 和 Hirai (2007) 展示了如何推广该计划以促进生产线的高效绩效。尽管如此,他们仍然专注于通过操纵规划算法来减少模型错误和计划失败的方法。数值方法因平面顺应性运动而受到赞誉,这种运动可以很好地抵消位置、方向和质量分布的不确定性。许多算法可能会为有保证的顺从运动创建完整的方法。

编码振动给料机通过在闭合钳口的稳定配置内旋转来执行柔顺运动。类似地,部件沿碗的滑动采取夹持器动作,该动作确定微部件的方向,而无需求助于传感器。在振动给料机配置中可能有效的其他方法是开环、不经意和无传感器操作。

b) Mechanical parts feeder

Some of the manufacturing processes are sensor-based while others do not require sensors. Binary vision systems are known for their ability to utilize sensors in orienting and coordinating parts within a mechanical actuator. Vibratory bowl feeder is a profound method that does not require sensors in its operations. Generally, the parts in the bowl are vibrated with a gyratory motion to enable them climb the helical track. 建筑学英文论文代写

Accordingly, a class of pins and the remaining cutouts in the tracks cause the parts to fall back into feeder bowl, allowing the desired parts to run through the gauntlet. When a new configuration of the parts is required, its geometry changes in respect to the helical track. Currently, there is no precise method of developing track geometry, not even vibratory bowl feeders. Trial and error techniques are sometimes applied to track the movement of the design, thus enabling creation of the required design (Mitani & Hirai, 2006, p 189-205).

Some vibratory feeders utilize array of nests on the vibrating plate.

These nest are designed such that they are aligned with the plate at a given instant. When the plate is tilted to allow the parts to flow, the nest is filled with the part to the desired level. Similarly, trial and error methods are applied in the design despite the control of the key processes being done by software.

In addition, more than one action is obligatory where there is adequate uncertainty in the orientation of the parts. The main challenge in the engineering field has been on developing a sustainable method of finding the sequences necessary for orienting the microparts. This would mean that a definite method could be developed by combining all the possible means of manufacturing work.

译文:

B) 机械零件进料器

一些制造过程是基于传感器的,而另一些则不需要传感器。二元视觉系统以其在机械致动器内定向和协调部件中利用传感器的能力而闻名。振动碗式给料机是一种无需传感器运行的深刻方法。通常,碗中的部件以回转运动振动,使它们能够爬上螺旋轨道。

因此,一类销钉和轨道中剩余的切口会导致零件落回进料器碗中,从而使所需零件穿过护手。当需要零件的新配置时,其几何形状会相对于螺旋轨道发生变化。目前,没有开发轨道几何形状的精确方法,甚至振动碗式给料机也没有。有时会应用试错技术来跟踪设计的运动,从而能够创建所需的设计(Mitani 和 Hirai,2006 年,第 189-205 页)。

一些振动给料机利用振动板上的巢阵列。

这些巢被设计成在给定的时刻与板对齐。当板倾斜以允许零件流动时,嵌套会被零件填充到所需的水平。同样,尽管关键过程的控制是由软件完成的,但在设计中还是应用了试错法。

此外,如果零件的方向存在足够的不确定性,则必须采取不止一种行动。工程领域的主要挑战是开发一种可持续的方法来寻找微部件定向所需的序列。这意味着可以通过结合所有可能的制造工作手段来开发一种明确的方法。

Review

Vibratory feeder bowl is a mechanical device that is utilized in factory automation. Both oblique and linear vibratory feeders are used for unidirectional feeding mechanisms. It is important to adjust both vertical and horizontal vibration ratios in order to prevent microparts from jumping. Moreover, static and sliding friction is essential in tracking the orientation executed by the moving parts. This means that the system has the ability to recognize unidirectional feeding by effecting the symmetric pulsation of a sawtoothed surface. This approach is attainable since different feeding systems produce varying forces on both positive and negative track. Notably, the movements of the microparts in the feeder bowl are much considered as opposed to the traditional manufacturing processes which were mainly concerned with the structure and actuator of the drive system (Pan & C.A Randall, 2010). 建筑学英文论文代写

Engineers have attempted to improve the drive efficiency using feedback control units, super injection techniques, molding and nonlinear resonance techniques. The current study focuses on the interaction between the feeder bowl and the microparts where the driving system is linked to the open loop feeding system. The direction of the microparts is controlled by air flowing through the micro-sized air nozzle. These movement might be manipulated further by ciliary systems and analyzing the vector fields. The feeder component has actuator arrays that are arranged to control the interaction between the vibratory plate and the microparts. With the modern growth in engineering, the magnetic, electro-magnetic and piezoelectric actuators are developed to support the ever booming manufacturing sector.

译文:

审查

振动给料碗是一种用于工厂自动化的机械设备。斜线和直线振动给料机都用于单向给料机构。调整垂直和水平振动比很重要,以防止微型零件跳跃。此外,静摩擦和滑动摩擦对于跟踪运动部件执行的方向至关重要。这意味着该系统能够通过影响锯齿状表面的对称脉动来识别单向进给。这种方法是可以实现的,因为不同的进给系统会在正轨和负轨上产生不同的力。值得注意的是,与主要与驱动系统的结构和执行器相关的传统制造工艺相反,进料器碗中微型零件的运动得到了更多的考虑(Pan & C.A Randall,2010)。

工程师们尝试使用反馈控制单元、超级注射技术、成型和非线性共振技术来提高驱动效率。目前的研究集中在进料碗和微型部件之间的相互作用,其中驱动系统与开环进料系统相连。微型零件的方向由流经微型空气喷嘴的空气控制。这些运动可能会被纤毛系统和分析矢量场进一步操纵。进料器组件具有致动器阵列,用于控制振动板和微型部件之间的相互作用。随着现代工程技术的发展,磁性、电磁和压电致动器被开发出来以支持不断发展的制造业。

Principles of unidirectional feeding

This principle is illustrated by evaluating the component and operational behavior of a capacitor. The approach is attained by developing a model which encourages contact between the microparts and the feeding bowl. An ideal capacitor consists of the dielectric material, a conductor and convexities on the top of each electrode. The contours on the surface of a capacitor are determined by Form Talysuff sensing tool.

When the electrodes are aligned with the feeder, they link creating a surge of 10µm. The radii of the convexities are obtained from integrating the components ᶲ-elevation angle, p-the saw pitch, and d-the depth of the feeder’s groove. Notably, the saw adopts two contact modes on the microparts; either at the tooth slope or at the tooth depth. The unidirectional movement of the microparts along the feeder bowl depends on feeder’s contact area and the orientation of the materials.

译文:

单向喂料原理 建筑学英文论文代写

通过评估电容器的组件和操作行为来说明该原理。 该方法是通过开发一个模型来实现的,该模型鼓励微型部件和喂食碗之间的接触。 理想的电容器由介电材料、导体和每个电极顶部的凸面组成。 电容器表面的轮廓由 Form Talysuff 传感工具确定。

当电极与馈线对齐时,它们会连接起来,产生 10µm 的浪涌。 凸面的半径是通过积分分量 ᶲ-仰角、p-锯距和 d-进料器凹槽的深度而获得的。 值得注意的是,锯在微零件上采用了两种接触方式; 无论是在齿坡处还是在齿深处。 微型零件沿进料器碗的单向运动取决于进料器的接触面积和材料的方向。

Introduction to ceramic capacitors used in vibratory feed bowl

Multilayer

It is widely used in the feeding bowl because it stores around 90% of the mechanical work that is used to drive the component. This model is characterized by a thick ceramic material which enables it to accommodate high capacitance and strong compactness. This capacitor is crucial in designing electronic devices which suits the preference of the consumers. For instance, Jupiter Electronic Company in Australia recorded an increment of 20% of the manufactured devices in 2012 compared to the performance in the previous years. This shows that the rate will surpass the articulation depicted in the Moore’s Law. This law states that the volume of electronic produced in a given environment will increase every year.

The role of capacitors in the vibratory feed bowl cannot be downplayed since the movement of the microparts is controlled automatically.

This means that an efficient and reliable form of power is necessary to accommodate the parts in the pushing process. The power factor of multilayer capacitors is reliable in large scale production of various designs in the manufacturing industries since both torque and vibratory forces are within tolerable levels (Ting, 2005, p 321). 建筑学英文论文代写

However, some companies limit applications of the ceramic capacitors since they are associated with catastrophic failures after running to a long time. Therefore, the operators are cautioned of being extra vigilant in working with this capacitor. Conventionally, the importance of multilayer ceramic capacitors (MLCCs) is evidenced in the vibratory feeder bowl because these capacitors are small-sized, reliable and operates at high frequencies.

译文:

振动给料碗用陶瓷电容器介绍

多层

它被广泛用于喂料碗,因为它存储了大约 90% 的用于驱动组件的机械功。该型号的特点是采用厚陶瓷材料,使其能够容纳高电容和强大的紧凑性。该电容器对于设计适合消费者偏好的电子设备至关重要。例如,澳大利亚的 Jupiter 电子公司在 2012 年记录的制造设备与前几年的表现相比增长了 20%。这表明该速率将超过摩尔定律中描述的清晰度。该法律规定,在特定环境中生产的电子产品数量每年都会增加。

由于微型零件的运动是自动控制的,因此不能低估电容器在振动进料碗中的作用。

这意味着需要一种高效且可靠的动力形式来适应推动过程中的零件。多层电容器的功率因数在制造业各种设计的大规模生产中是可靠的,因为扭矩和振动力都在可容忍的范围内(Ting,2005,第 321 页)。

然而,一些公司限制了陶瓷电容器的应用,因为它们在运行很长时间后与灾难性故障有关。因此,提醒操作人员在使用该电容器时要格外小心。传统上,多层陶瓷电容器 (MLCC) 的重要性在振动给料器碗中得到证明,因为这些电容器尺寸小、可靠且可在高频下运行。

Single layer capacitor

This capacitor is alternated with the multiple layer capacitors since it has a high form factor. Its resonance is derived from the frequency and speed of the movement of microparts in the feeder bowl. The thickness of the dielectric material in the ceramic capacitor is approximately 5 mm. The integrated circuits of these capacitors are depicted on the initial usage manual. This feature also indicates the chip carriers, dimensions and various vibratory speeds which feeder bowl should be configured. 建筑学英文论文代写

The electrodes of the ceramic capacitor are linked to the feeder by a connective part which transfers the torque to the capacitor for storage. Commonest chip capacitors are manufactured by metalizing both surfaces of the thin sheets, thus preventing flux leakage. Typical ceramic sheets are cut by abrasive techniques in size ranging from 6 mm to 50 mm. Note that overloading the bowl with microparts limits the efficiency of the capacitor, thus minimizing the efficiency and reliability of the production model.

译文:

单层电容器

该电容器与多层电容器交替使用,因为它具有高外形尺寸。其共振源自进料碗中微型零件运动的频率和速度。陶瓷电容器中介电材料的厚度约为 5 毫米。这些电容器的集成电路在初始使用手册中有描述。此特征还指示应配置哪些进料器碗的切屑载体、尺寸和各种振动速度。

陶瓷电容器的电极通过连接部分连接到馈线,该连接部分将扭矩传递到电容器进行存储。最常见的片式电容器是通过对薄片的两个表面进行金属化来制造的,从而防止漏磁。典型的陶瓷片是通过研磨技术切割的,尺寸范围从 6 毫米到 50 毫米。请注意,使用微型零件使碗过载会限制电容器的效率,从而最大限度地降低生产模型的效率和可靠性。

Ceramic dielectric materials

The commonly used ceramic materials for fabricating capacitors used in feeder bowl have high dielectric properties. Dielectric constants take values from 5 to 20,000µm. These values are used to classify the ceramic capacitors as follows:

- Class 1 dielectrics: They possess low ceramics with a dissipation factor of less than 0.001. They have constant temperature coefficients which prescribe permittivity within a wide tolerance. 建筑学英文论文代写

- Class 2 dielectrics: They have high ceramic ranging from 1,000 to 20,000 depending on the ferroelectric properties which ranges from 0.01 to 0.04.

- Class 3 dielectrics: They are design such they form a barrier layer in capacitors. Re-oxidation process occurs in each grain of the capacitor, developing a thin insulating layer.

译文:

陶瓷介电材料 建筑学英文论文代写

馈线碗中常用的制造电容器的陶瓷材料具有高介电性能。 介电常数取值从 5 到 20,000μm。 这些值用于对陶瓷电容器进行如下分类:

- 1 类电介质:它们具有耗散因数小于 0.001 的低陶瓷。 它们具有恒定的温度系数,可在很宽的容差范围内规定介电常数。

- 2 类电介质:根据铁电特性范围从 0.01 到 0.04,它们具有范围从 1,000 到 20,000 的高陶瓷。

- 3 类电介质:它们被设计成在电容器中形成阻挡层。 再氧化过程发生在电容器的每个晶粒中,形成薄绝缘层。

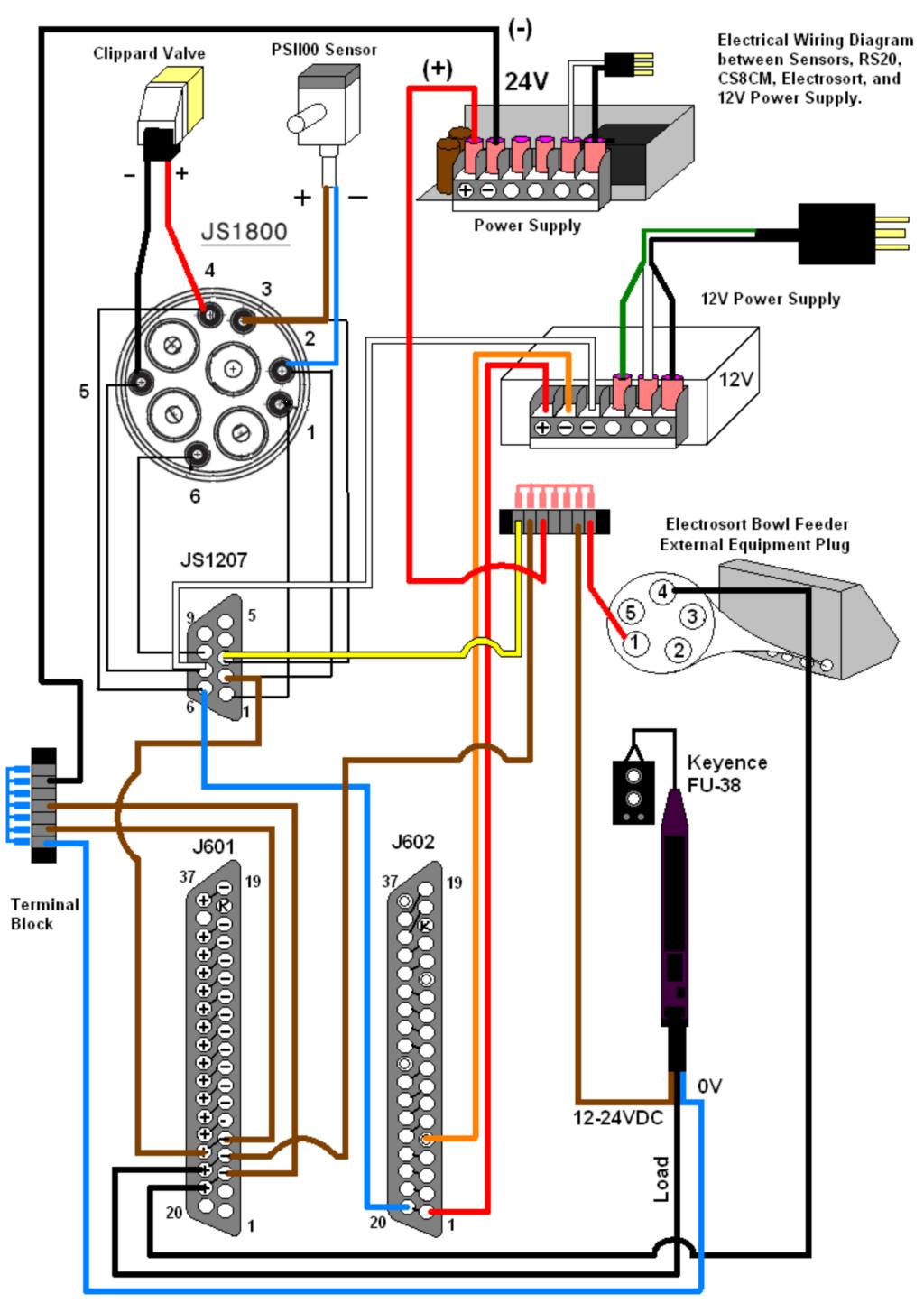

Electrosort bowl feeder

This is a mechanical device designed for organizing transferring and setting microparts on the bowl feeder. Bowl feeders are applied to feeding microparts such as the capacitors and ceramic materials into the production process. This development was first developed in 1956 with a trade name, A-B Tool & Advanced Manufacturing. The founding company of this component later limited its focus on growing demand of the conductors and ceramic components industries. This resulted in development of chip and filtering systems in the engineering division. Later on, Electrosort Automation was coined from manufacturing division, focusing on the operations that major with precision and quality products (Mitani & Hirai, 2006).

Electrosort bowl feeder is efficient mechanical tool for feeding microparts into the desired shape.

It has a vibratory bowl feeder that oscillates the parts in a linear feeder. This is followed by alignment of the parts in a straight line, and synthesized to the bowl plate where pickup occurs. 建筑学英文论文代写

The efficiency of this system is maintained by an optic sensor which detects the location of the parts on the linear feeder, thus preventing overloading of the component. The bowl feeder sends signals to the collector when the microparts are on the pickup location, turning it off and opening the output device for collection of the parts (Maul & Thomas, 1997). The feeding rates of the parts ranges from 30,000 to 50,000 parts per hour depending on the mechanical properties, size and quality of the parts. Beam optic is manipulated depending on the operational rates of the feeder to prevent damage on the parts, hence quality products.

译文:

Electrosort 碗进料器 建筑学英文论文代写

这是一种机械装置,用于在碗式送料器上组织传送和设置微零件。碗状送料机用于将电容器、陶瓷材料等微细零件送入生产过程。该开发项目于 1956 年首次开发,商品名为 A-B Tool & Advanced Manufacturing。该组件的创始公司后来将其重点放在导体和陶瓷组件行业不断增长的需求上。这导致了工程部门开发了芯片和过滤系统。后来,Electrosort Automation 由制造部门创造出来,专注于以精密和优质产品为主的运营(Mitani & Hirai,2006)。

Electrosort 碗式送料器是一种高效的机械工具,用于将微型零件送入所需形状。

它有一个振动碗式送料器,可在线性送料器中振动零件。随后将零件对齐成一条直线,并合成到发生拾取的碗盘上。

该系统的效率由光学传感器保持,该传感器检测线性进料器上零件的位置,从而防止零件过载。当微型零件位于拾取位置时,碗式送料器向收集器发送信号,关闭它并打开输出设备以收集零件 (Maul & Thomas, 1997)。根据零件的机械性能、尺寸和质量,零件的进料速度为每小时 30,000 至 50,000 个零件。根据供料器的运行速率来操纵光束光学元件,以防止损坏零件,从而确保产品质量。

Feeding simulation and comparisons

This is achieved effectively by analyzing the feeding dynamics of the system. The convexities on capacitor’s electrodes are assumed to be half sphere. The diameters and radii of the convexities are defined in a 3D model with the contour lines indicating the location of the G-xy coordinates of the microparts. The system should account for all convexities on the capacitor in order to promote successful analysis. Both x1x1 and y1y1 line should be parallel to their respective coordinates; x and y axis. The analysis indicates that each convexity is approximately half sphere with an average capacitance of 18µm. In addition, each convexity is defined by radii from both coordinates.

In dynamics, both feeder’s coordiates and position of the microparts are defined as O-x0y0 and P= (xb, yb, ⱷ).

Subsequently, dynamics of microparts are analyzed using matrix approach to facilitate defining the ith convexity of the capacitor. The G-xy coordinate indicates the ith convexity as Fi= (xi, yi) and Ci= (xi, yi). Inertia, mass, and attenuation of motion are determined using this approach. Moreover, the analysis method is essential in calculating torque and the driving force of the vibratory feeder bowl. This is done by adding the driving forces from the electrodes of the capacitors. Considering the torque, f= (Fx, Fy, )ᵟ, vibration of the feeder could be configured (Wolfsteiner & Pfeiffer, 1999, p 189-199). 建筑学英文论文代写

The above equations are manipulated while calculating the force developed between the convexities and sawtooth. The feed velocity at peak should be within a narrow range of 0.04 mm. Manufacturing engineers argues that the sawtooth pitch should be proportional to the velocities of the feeder to promote creating controllable simulations. Accordingly, the pitch of 0.01 to 0.05 mm produces simulations of slower rate than a pitch of 0.06 to 0.1 mm.

译文:

喂养模拟和比较 建筑学英文论文代写

这是通过分析系统的进料动态有效地实现的。电容器电极上的凸面被假定为半球。凸面的直径和半径在 3D 模型中定义,轮廓线表示微零件的 G-xy 坐标的位置。该系统应考虑电容器上的所有凸面,以促进成功的分析。 x1x1 和 y1y1 线都应该平行于它们各自的坐标; x 和 y 轴。分析表明,每个凸面近似为半球,平均电容为 18µm。此外,每个凸度都由两个坐标的半径定义。

在动力学中,进料器的坐标和微部件的位置都定义为 O-X0Y0 和 P= (XB, YB, ⱷ)。

随后,使用矩阵方法分析微零件的动力学,以方便定义电容器的第 i 个凸度。 G-xy坐标表示第i个凸度为Fi=(xi,yi)和Ci=(xi,yi)。使用这种方法确定运动的惯性、质量和衰减。此外,分析方法对于计算振动给料碗的扭矩和驱动力至关重要。这是通过添加来自电容器电极的驱动力来完成的。考虑到扭矩 f= (Fx, Fy, )ᵟ,可以配置馈线的振动 (Wolfsteiner & Pfeiffer, 1999, p 189-199)。

在计算凸面和锯齿之间产生的力时,可以操作上述方程。峰值进给速度应在 0.04 毫米的窄范围内。制造工程师认为锯齿节距应该与馈线的速度成正比,以促进创建可控的模拟。因此,0.01 到 0.05 毫米的节距比 0.06 到 0.1 毫米的节距产生更慢速率的模拟。

Conclusion

This paper has evaluated the behavior of the vibratory feeder bowl under orientation of microparts. Still, the vibratory manipulation of the feeder produces repeated degrees of high frequency and relatively low amplitude. The study has shown that the rotating motion of the feeder bowl generates two forms of manipulations: intermittent and continuous tapping.

In one dimensional case, it is easy to characterize the configuration taken by the feeder in the space. The measurement taken within the design tolerances are essential in deciding the volume of microparts that should be fed into the vibratory feeder bowl at a given time. The sensory device helps the operator to time the input and the output which sustains the operations of a feeder bowl. 建筑学英文论文代写

It is noted that utilization of the vibratory manipulation is useful in describing the the periodic motion adopted by the feeder bowl. Motion constraints such as pushing are developed from the capacitors which play an important role in this model. Actually, they stores high percentage of power which facilitates achieving various production processes. A robustic manipulation process could result in development of a reliable vibratory feeder bowl or nest that resonates with open-loop vibration model. Moreover, algorithms are involved when developing a feeder bowl from geometric plan (Wakino & Tamura, 2001, p 212- 220).

Finally, the study indicated that capacitors can rotate around the vertical axis of the sawtooth, in both lengthwise and widthwise postures. This movement helps the microparts to move in the feeder with minimal hesitation.

译文:

结论 建筑学英文论文代写

本文评估了振动给料碗在微零件定向下的行为。尽管如此,馈线的振动操作仍会产生重复程度的高频和相对较低的振幅。研究表明,喂食器碗的旋转运动会产生两种形式的操作:间歇性和连续性敲击。

在一维情况下,很容易表征空间中馈线所采用的配置。在设计公差范围内进行的测量对于决定在给定时间应送入振动进料器碗的微型零件的体积至关重要。传感装置可帮助操作员对维持喂料碗运行的输入和输出进行计时。

值得注意的是,利用振动操作来描述给料碗采用的周期性运动是有用的。诸如推动之类的运动约束是从在该模型中发挥重要作用的电容器发展而来的。实际上,它们存储了高百分比的电力,这有助于实现各种生产过程。稳健的操作过程可能会导致开发可靠的振动给料器碗或巢,与开环振动模型共振。此外,在根据几何平面开发喂食碗时,会涉及算法(Wakino 和 Tamura,2001,第 212-220 页)。

最后,研究表明电容器可以在纵向和横向两种姿势下围绕锯齿的垂直轴旋转。这种运动有助于微零件以最小的犹豫在进料器中移动。

References 建筑学英文论文代写

Maul and Thomas. A systems model and simulation of the vibratory bowl feeder, Journal of

Manufacturing System: Wiley Pub. Co, 1997. Print.

Mitani and Hirai. Micro-parts Feeding by a Saw-tooth Surface, IEEE/ASME Transactions on

Mechatronics: Pearson, 2006. Print.

Pan, Ming-Jen, and C.A Randall. A Brief Introduction to Ceramic Capacitors: Electrical

Insulation Magazine, IEEE, 2010. Print.

Ting, Y. A new type of parts feeder driven by bimorph piezo actuator: Pearson, 2005. Print.

Wakino, K. and H. Tamura. Low-loss Ceramics in Mobile Communications. Encyclopedia of

Materials: Science and Technology: Graceway Pub.Co. 2001. Print.

Wolfsteiner and Pfeiffer. The parts transportation in a vibratory feeder, Processes: 1999. Print.

Appendices

Vibratory center discharge

Vibratory feeder variable feeder controller

A vibratory feeder bowl for microparts.

更多代写:程序代写 财务Online exam代考 波士顿essay代写 毕业Essay代写 本科论文代写 雅思机考可以作弊吗